The Plastic Predicament

The journey in unwrapping a viable alternative

With food it can be easy to take for granted the consistent supply, the varieties, and the sheer convenience available to us in our day-to-day life.

There are many technological and societal changes that have led us to this point, but the one in particular that has overshadowed the marvels of our modern food systems, is the reliance on plastics.

As a food manufacturer, we have a responsibility towards educating and advocating for a more sustainable attitude towards food packaging and a more environmentally-conscious approach to plastics.

Read about our ongoing journey towards future food packaging technologies – the possibilities, the pitfalls, and the realities.

The APCO Partnership

The Australian Packaging Covenant Organisation (APCO) is a not for profit organisation leading the development of a circular economy for packaging in Australia.

Their vision is a packaging value chain that collaborates to keep packaging materials out of landfill and retains the maximum value of the materials, energy and labour within the local economy.

APCO work with governments, businesses and other organisations from across Australia’s large and complex packaging value chain to develop the insights, resources and programs that are needed to build a sustainable national packaging ecosystem.

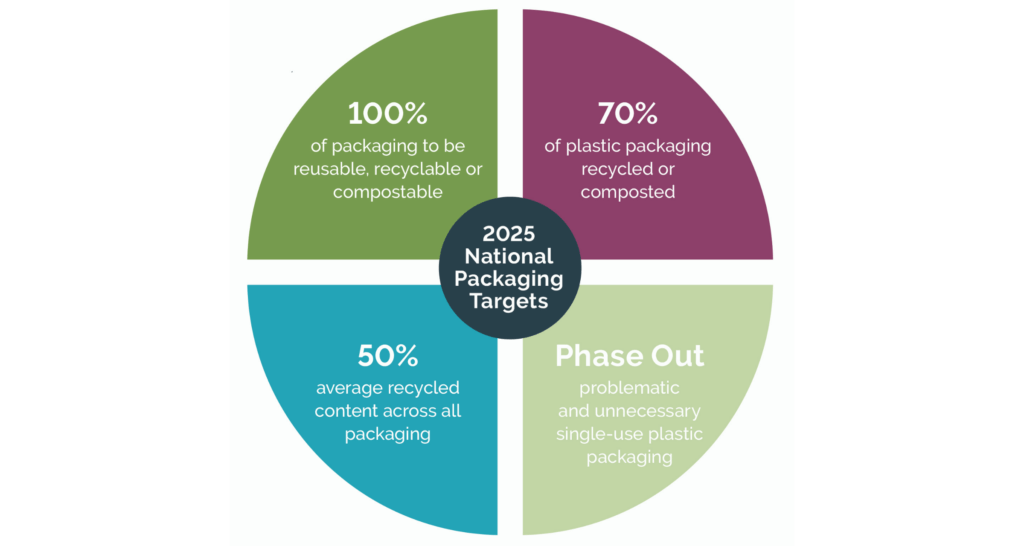

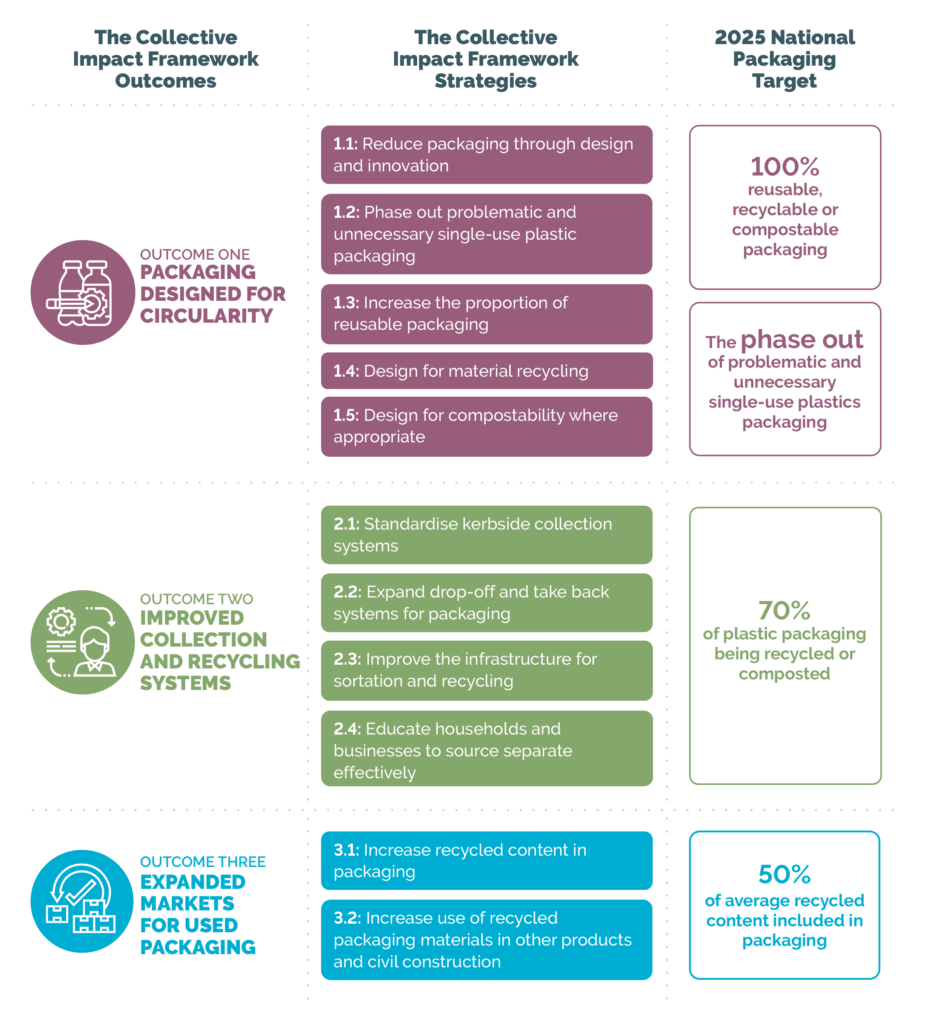

This includes facilitating the delivery of Australia’s 2025 National Packaging Targets, an important step on the pathway to a circular economy.

All of their work is underpinned by the Collective Impact Framework, a powerful cross-sector collaboration tool that unites a diverse range of stakeholders from across the value chain behind APCO’s common vision.

They deliver this model of shared responsibility through the promotion of circular packaging design, working to improve collection and recycling systems and education, and expanding markets for used packaging.

There’s a reason that plastic has become so ubiquitous in all forms of packaging, and in particular food.

Its ability to provide an airtight seal is one of the most important properties of plastic.

As these materials only possess some, but not all of the essential food-protecting properties of plastic, they do not represent a perfect alternative.

These materials require plastic to be incorporated in some way in order to achieve all of the necessary food safety properties.

Whilst some of these options may reduce the amount of plastic material used in a given package, the ability to recycle certain composite materials is limited or non-existent.

Developments in technology have seen corn and other vegetable-based biofilms become widely available, which have provided plastic-like materials that are biodegradable and compostable.

Unfortunately, such materials are far from suitable for most retailed food products. These biofilms provide only short-term protection for foods that are already hardy by their nature, e.g. dry goods like rice, beans or legumes – but the most important limitation is that they cannot form an airtight seal.

Rather than focussing only on the package at arms-length, we should also gain perspective across the entire journey of food from manufacturer to consumer.

It could be a system of reusable and returnable food containers for products (currently being tested in partnership by some manufacturers and retailers).

We must consider how can we adapt our attitude and expectations of how we should consume food. This could mean purchasing in bulk rather than in small recurring amounts.

Recycling your single-use plastics (including Whisk & Pin product packaging) is currently the best way to dispose of them, and to minimize further impacts to the environment.

By returning your soft plastics to a REDcycle drop-off point, you’re ensuring that these plastics are kept out of landfill and waterways. REDcycle collected plastics are sorted and processed in Melbourne, where they are then distributed to one of many local manufacturers.

Visit Replas to understand how your recycled soft plastics may be repurposed and manufactured into new products like school furniture.